DOC

DOC

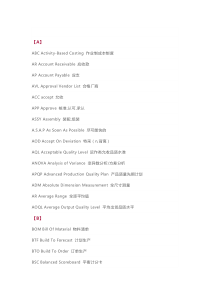

【文档说明】质量管理术语英语简写.docx,共(21)页,23.523 KB,由小魏子文库上传

转载请保留链接:https://www.ichengzhen.cn/view-320375.html

以下为本文档部分文字说明:

【A】ABCActivity-BasedCosting作业制成本制度ARAccountReceivable应收款APAccountPayable应支AVLApprovalVendorList合格厂商ACCaccept允收AP

PApprove核准,认可,承认ASSYAssembly装配,组装A.S.A.PAsSoonAsPossible尽可能快的AODAcceptOnDeviation特采(n,背离)AQLAcceptableQua

lityLevel运作类允收品质水准ANOVAAnalysisofVariance变异数分析/方差分析APQPAdvancedProductionQualityPlan产品质量先期计划ADMAbsoluteDimensionMeasurement全尺寸测量ARA

verageRange全距平均值AOQLAverageOutputQualityLevel平均出货品质水平【B】BOMBillOfMaterial物料清单BTFBuildToForecast计划生产BTOBuildToOrder订单生产BS

CBalancedScoreboard平衡计分卡【C】CARCorrectiveActionRequest改进对策要求CARCorrectionActionReport改善报告CPMComplaintperMillion每一百万个使用者会有几次抱怨CPMCriticalP

athMethod要径法CRMCustomerRelationshipManagement客户关系管理CRPCapacityRequirementsPlanning产能需求规划CSCustomerSatisfa

ction顾客满意度CSCustomerService顾客服务CTOConfigurationToOrder客制化生产CTQCriticaltoquality质量关键COGSCostOfGoodsSold销售成本CQACustomerQualityAssurance客户

品质保证CSACustomerSimulateAnalysis客户模拟分析CIPContinualImprovementPlan持续改善计划CRAcorrectiveactionreport改正行动报告(改善报告)CONConcession/Waive特采CATCarria

geAlignmentTool载器调整具CRCritical极严重的CPcapabilityindex能力指数/准确度C=0Critical=0极严重不允许CHKCheck确认CPUCentralProcessingUnit中央处理器CTNCarton卡通箱CPK

capabilityprocessindex过程能力参数Conformity合格(符合)Characteristic特性continualimprovement持续改进Correction纠正Costdown降低成本Confi

denceinterval信赖区间Controlchart管制图CauseandEffectmatrix因果图.鱼骨图Centerline中心线check检查CheckSheet查检表CharacteristicDiagram特性要因图Complaint投诉CP

I:continuousProcessImprovement连续工序改善【D】DIMDimension尺寸DIADiameter直径DWGDrawing图面DCDocumentCenter资料中心D/CDateCode

生产日期码DQADesignQualityAssurance设计品质保证DOEDesignofExperiments实验设计DCCDocumentControlCenter数据控制中心DPPMDefectiv

ePiecesPerMillionunits百万件中有损件数DPMODefectspermillionopportunities每百万个机会的缺点数DPUDefectsperunit单位缺点数DFSSDesignforsixsigm

a六个希格玛设计DOEDesignofexperiment实验设计DVTDesignVerificationTesting设计验证DSSDecisionSupportSystem决策支持系统DCNDesignChangeNotice设计变更通知DMRDefectiveMaterialRepo

rt材料缺陷报告DWGDrawing图面系统文件类DOEDesignofExperiments实验设计DSADefectsAnalysisSystem缺陷分析系统DataCollection数据收集Description描述Device装置Digital数字

Do执行Designofmanufacturing制造设计deviationpermit偏离许可degrade降级designanddevelopment设计和开发dependability可信性Defect缺陷Decision决心Data数据DataCollect

ion数据收集Dataconcentrator资料集中缓存器Decision决策.判定Defectsperunit单位缺点数Description描述Detection难检度Device装置Digital数字Do执行【E】ECEngineerChange设计变更/工程变更ECElectronic

Commerce电子商务EMCElectricMagneticCapability电磁相容EOQEconomicOrderQuantity基本经济订购量ERPEnterpriseResourcePlanning企业资源规划ECNEngineeringChangeNo

tice工程变更通知(供货商)ECOEngineeringChangeOrder工程改动要求(客户)ERSExternalReferenceSpec外部规格ERPEnterpriseResourceProgramming企业资源项目ESEngin

eeringStandard工程标准E-MAILElectrical-Mail电子邮件EAREngineeringAnalysisRequest工程分析要求EVEquipmentVariation设备变异ES

EngineeringStandardization工程标准Environmental环境Equipment设备Effectiveness有效性Efficiency效率Element元素Else否则Engineeringtechnolog

y工程技术Entropy函数Estimatedaccumulativefrequency计算估计累计数ExternalFailure外部失效,外部缺陷Event事件【F】FMEAFailureModea

ndEffectanalysis失效模式与效果分析FAFailureAnalysis不良分析FQAFinalQualityAssurance最终品质保证FQCFinalQualitycontrol最终品质控制FAIfirstarticleinspecti

on首件检查FAAfirstarticleassurance首件确认FPIRFirstPieceInspectionReport首件检查报告F/TFunctionTest功能测试FMSFlexibleManufactureSystem弹性制造系统FQC

FinishorFinalQualityControl成品质量管理FGIFinishedgoodsInventory成品存货FTAFaultTreeAnalysis故障树分析FREQFrequency频率FINFina

nce财务FixOHFixOverhead固定管理费用FinanceAccounting财务账目Failurerate故障率Factcontrol事实管理FPY合格率Full-steer完全转向function职能【G】GSGeneralSpecifica

tion一般规格GRRGaugeReproducibility&Repeatability量具之再制性及重测性判断量测可靠与否Gaugesystem量测系统Grade等级GeneralAffair总务【H】H/Whardware硬件H/THighTemperatureTest高温测试HQHead

quarter总公司HRHumanResource人力资源部Histogram直方图Hypothesistesting假设检定Healthmeter体重计Heatpress冲压粘着Hi-tech高科技【I】IMDImageManagementDivi

sion影像管理事业部ITSInformationTechnologySystem计算机部IPQCInProcessQualityControl制程品质控制IQCIncomingQualityControl来料品质控制IWSInternationalWorkmanStandard工艺标准I

SOInternationalStandardOrganization国际标准化组织ISInspectionSpecification成品检验规范IEIndustrialEngineering工业工程ID/CIdentificationCode(供货商)识别码IDIndustrialDesi

gn工业设计(外观设计)ISInformationSystem资讯系统ITInformationTechnology系统技术ISARInitialSampleApprovalRequest首批样品认可I/Oinp

ut/output输入/输出Improvement改善Inductance电感Information信息Initialreview先期审查Inspection检验InternalFailure内部失效,内部缺陷Interestedparty相关方Infrastructure基础设施I

nspection检验【J】JITJustInTime实时管理JQEJointQualityEngineer客服工程师【L】LCLLowerControllimit管制下限LQCLineQualityControl生产线品质控制LQLLi

mitingQualityLevel最低品质水准L/TLeadTime前置时间(生产前准备时间)LRRLotRejectRate批退率LSLLowerSizeLimit规格下限L/TLowTemperatureTest低温测试L/NLotNumber批号LABLaborator

y实验室LPCLLowerPer-controlLimit前置管制下限Love爱心Link连接LifeTest寿命测试Lawoflargenumber大数法则【M】MSAMeasurementSystemAnalysis量测系统分析MPSMassProduct

ionSchedule量产计划MTFModulationTransferFunction调整转换功能MCMaterialControl物料控制MVTMassVerificationTest多项验证测试MIL-STDMi

litaryStandard军用标准MISManagementInformationSystem管理资讯系统MTBFMeanTimeBetweenFailure平均故障间隔MAJMajor主要的MINMinor轻微的MINMinimum最小值MAXMaximum

最大值MQAManufactureQualityAssurance制造品质保证MRPMaterialRequirementPlanning物料需求计划MRBMaterialReviewBoard物料评审委员会MRBMaterialRejectBill退货单MOManufact

ureOrder生产单MFGManufacturing制造部MESManufacturingExecutionSystem制造执行系统managementsystem管理体系Materials物料Measuremen

t量测management管理Machine机械Materials物料Median中位数Missfeed漏送Momentum原动力Multiplicationrule乘法运算规则【N】N/ANotApplicable不适用NGNotGood不行,不合格NNumber样品数NFCFNotice

forChangingForecast更改预估量的通知Nonconformity不合格(不符合)Normaldistribution常态分配【O】OQAoutputqualityassurance出货质量保证OQCOutgoingQualityContro

l出货质量控制OPTOptimizedProductionTechnology最佳生产技术ORTOnGoingReliabilityTest出货可靠性测试OBAOpenBoxAudit成品检验OEMOriginalEquipmentManufacture原

设备制造OBAoutofboxaudit开箱检查Occurrence发生率Organization组织organizationalstructure组织结构OperationInstruction作业指导书【P】PRPublicrelation公共关系PCNProcessChange

Notice工序改动通知PMPProductManagementPlan生产管制计划PMCProduction&MaterialControl生产和物料控制PCCProductcontrolcenter生产管制中心PPCProductionPlanControl生产计划

控制P&LProfit&Lose利润与损失PVPerformanceVariance性能差异PRSPairs双(对等)POPurchasingOrder采购订单PDProductDepartment生产部POCpassagequal

itycontrol检人员P/NPartNumber番号PPMPercentPerMillion百万分之一PSPackageSpecification包装规范PDProductDepartment生产部

PCBAPrintedCircuitBoardAssembly电路板组装PVTProductionVerificationTest生产验证测试PDCAPlan-Do-Check-Action管理循环PQCprocessqualitycontrol制程检查管制P

QAProcessQualityAssurance制程品质保证PPAPProductionPartsApprovalProcedure生产件批准程序PCLPer-controlCentralLimit前置管制中心限POPurchaseOr

der订单PURPurchasing采购President总裁preventiveaction预防措施PlatoDiagram柏拉图Parameter参数Part零件Pulse脉冲Policy方针Procedure流程Process过程Pr

oduct产品Production生产Program方案Projects项目Progress进步Passive消极的,被动的Population群体Power力量,能源Practice实务Precision精密度preemptive先占式多任务Pressure压缩Prevention预防Pro

bability机率Probabilitydensityfunction机率密度函数Processcapabilityanalysis制程能力分析图Processcontrolandprocesscapability制程管制与制程能力Producer’srisk生产者之风险【Q】QAQualit

yAssurance品质保证QCQualityControl品质控制QEQualityEngineering品质工程QFDQualityFunctionDesign品质架构设计OQAoutputqualityassurance出货质量保证人员QRAQua

lity&ReliabilityAssurance质量与可靠性保证QEQualityEngineer质量工程师QRAQualityReliabilityAssurance品保部QCCQualityControlCircle品管圈QPQualityPolicy目标方针QITQu

alityImprovementTeam品质改善小组QIQualityImprovement品质改善Q/R/SQuality/Reliability/Service品质/可靠度/服务QTYQuantity数量QVLQua

lifiedVendorList合格厂商QFDqualityfunctiondeployment质量机能展开QSQualitySystem品质系统QRAQualityReliabilityAssurance品质保证(处)QSAQua

litySystemAudit品质系统审核QTQualityTarget品质目标QCPQualityControlProcedures品管程序qualityobjective质量目标qualitypla

n质量计划qualificationprocess鉴定过程Qualitymanual品质手册【R】RMAReturnMaterialAudit退料认可R&DResearch&Design设计开发部RMAReturnMaterialAdministration材料回收管理RMAReturnedMa

terialApproval退货验收ROPRe-OrderPoint再订购点REEReject拒收RMAReturnMaterialAuthorization/Authority退料认可RPNRiskPriorityNumber风险系数Record记录Refl

ow回流Repair返修Repeatability可重复性Reproducibility再现性Requirement要求Residual剩余的,残留的Response响应Responsibilities职责Review评审Rework返工Rolledyield直通率Release放行Ran

ge全距Randomexperiment随机试验Randomnumbers随机数Range全距Reject拒收Response响应Responsibility职责Robustness稳健性Rolledyield直通率【S】SOPStandardOperat

ionProcedure标准作业书SPCStatisticalProcessControl统计制程管制SQASource(Supplier)QualityAssurance供应商品质保证SIPStandardInspe

ctionProcedure制程检验标准程序SOPStandardOperationProcedure制造作业规范SPCStatisticalProcessControl统计过程管制SQCStatisticalQualityControl统计质量管理SSQAs

tandardizedsupplierqualityaudit合格供货商品质评估S/SSamplesize抽样检验样本大小SQAStrategyQualityAssurance策略品质保证SSQASalesan

dserviceQualityAssurance销售及服务品质保证SPECSpecification规格SWRSpecialWorkRequest特殊工作需求SAPSystemApplicationProgramming体系运行计划S/Wsoftware软件SFCSh

opFloorControl现场控制SOSalesOrder订单SIPSpecificationInspectionProcess制程检验规格SQMSupplierQualityManagement供应商品质管理SL

SizeLine规格中心线Stratification层别法System体系(系统)Sales销售Supplier供方sample抽样,样本Scrap报废sample抽样,样本Scatterdiagram散布图分析Screw螺旋Severity严重度Size

规格Slip滑动Specialcause特殊原因Specification规范Stagesampling分段随机抽样statisticaltable统计(数值)表Sumofsquares统计表systematicsampling系统抽样Samplespace样本空间Simple

randomsampling简单随机取样Stratifiedrandomsampling分层随机抽样Samplingwithreplacement放回抽样Samplingwithoutreplaceme

nt不放回抽样【T】TQCTotalQualityControl全面品质控制TQMTotalQualityManagement全面品质管理TPMTotalProductionMaintenance全面生产保养T/PTruePosition真位度T/CTemperatureCy

cle温度循环T/OTurnOverRate=Monthly周转率TOCTheoryofConstraints限制理论TVRtoolverificationreport模具确认报告Taguchi-method田口方法topmanagement最高管

理者Test试验traceability可追溯性Technicalcommittees技术委员会Testpiece测试片Theory原理Timestamp时间戳印Time-lag延迟Title标题Torque转矩Total求和Tr

aceability追溯Training培训Trouble困扰Transactionprocessingandlogging交易处理【U】UCLUpperControlLimit管制上限USLUpperSizeLi

mit规格上限UTSUnitsToStock存货单元UPCLUpperPer-controlLimit前置管制上限Upanddown上和下【V】VQMendorQualityManagement厂商质量

管理VMIVisualMechanicalInspection外观机构检验VOCvoiceofCustomer客户需求VOEVoiceofEngineer工程需求VicePresident副总裁Verifi

cation验证Validation确认Variable计量值Version版本Vector向量【W】WIPWorkInProcess在制品WDRWeeklyDeliveryRequirement周出货要求workenvironment工作环境【Z】ZDZeroDefect零缺点

辽公网安备 21102102000191号

辽公网安备 21102102000191号

营业执照

营业执照